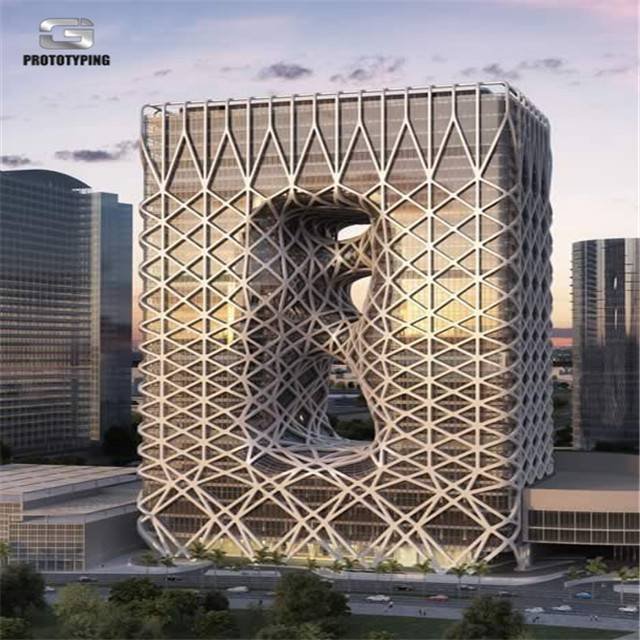

Zaha hadid design -- Morpheus Hotel in Macau

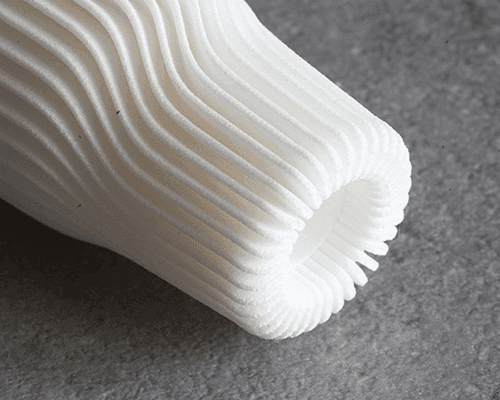

SLA & SLS PRINTING

SLA & SLS PRINTING

As the 3D printing technology applications leading enterprises, we provide customers based on 3D printing technology from R & D to manufacturing a full range of one-stop service,we offer stereolithography (SLA) and selective laser sintering (SLS).

WHAT IS SLA AND SLS?

Light curing process, also referred to as SL is called a stereolithography rapid prototyping process belongs to, also sometimes referred to as SLA. the process is a RP process developed in 1986 in the United States, 1987 by the United States patent, is the earliest and most mature technology and application of rapid prototyping technology is the most widely. With photosensitive resin as raw material, through the computer control of ultraviolet laser stone layer solidification. This method is simple, automatic manufacturing of surface quality and size precision, complex geometry of the prototype.

Sintering, referred to as SLS, using infrared laser to powder material (nylon, nylon fiber, nylon fiber, nylon powder, PS materials and various metal materials include: die steel, titanium alloy, Aluminum Alloy and CoCrMo alloy, nickel iron alloy etc.) directly sintering. EOS EOSINT M280, representative: P395, is a leading global metal forming and plastic molding equipment.

SLA & SLS PROTOTYPING

SLA and SLS services allow you to make 3D printed parts and prototypes in a range of plastics. Prototypes made using this service can be used for engineering testing or as master models for polyurethane vacuum casting molds. SLA and SLS both allow the product designer to quickly create complex shapes that cannot be made with conventional subtractive methods. You can also have metal 3D printed parts made using our DMLM service.

ADVANTAGES OF SLA AND SLS

There are advantages and disadvantages to both techniques that should be considered carefully to achieve the desired results.

SLA produces a part with:

A good, smooth surface finish and fine resolution

Better surface quality

Forming precision is high, the precision is about 0.1mm

System resolution is higher

SLA produces a part with:

Can use a variety of materials

Manufacturing process is relatively simple

High precision

No need to support the structure

The material utilization rate is high

Short production cycle, which makes it particularly suitable for the development of new products

Combined with the traditional process, it can realize the function of rapid casting, rapid tooling, small batch output, etc

APPLICATION AREA:

MATERIALS:

TOLERANCES:

TO START FOR YOUR PROJECT?

-

Zaha hadid design -- Morpheus Hotel in Macau

Zaha hadid design -- Morpheus Hotel in Macau -

SLA 3D Printed Chinese Dragon

SLA 3D Printed Chinese Dragon -

custom 3d printing service sla/sls printing processing introduction

custom 3d printing service sla/sls printing processing introduction -

How is vacuum casting prototyping working?And why you choose this process from us?

How is vacuum casting prototyping working?And why you choose this process from us? -

High quality Prototyping China - Rapid Prototyping 3D Printing

High quality Prototyping China - Rapid Prototyping 3D Printing -

Scent bottle by transparent PMMA plus electroplating top cap

-

High polished surface aluminum components

High polished surface aluminum components -

Transparent acrylic box used with cnc machining milling service

Transparent acrylic box used with cnc machining milling service -

High Polished Aluminum 6061 by CNC machining

High Polished Aluminum 6061 by CNC machining -

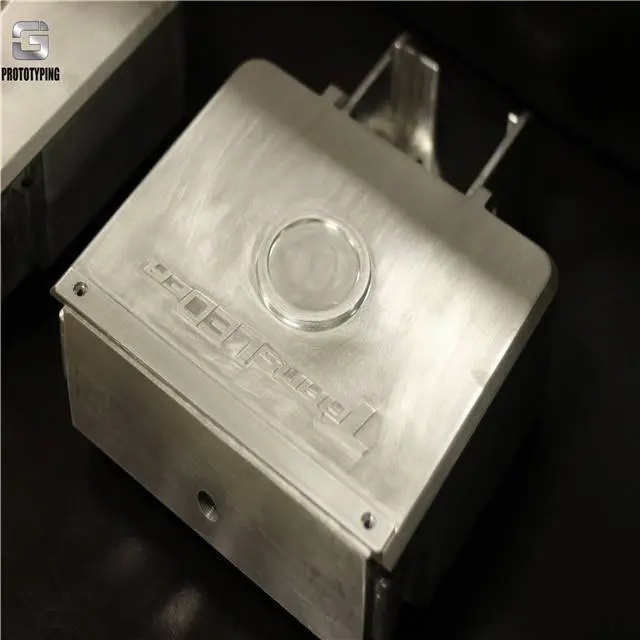

Aluminum 6061 boxes plus LOGO CNC machining

Aluminum 6061 boxes plus LOGO CNC machining -

Stainless Steel 304 CNC machining +-0.1mm

Stainless Steel 304 CNC machining +-0.1mm -

Polished brass components by CNC machining

Polished brass components by CNC machining -

CNC milling machining service andanodized color aluminum 6061 6063 box

CNC milling machining service andanodized color aluminum 6061 6063 box -

Polished brass keyboard CNC machining

Polished brass keyboard CNC machining -

Aluminum 6061 shoes model

Aluminum 6061 shoes model -

Matt black car components

Matt black car components -

High polished aluminum components

High polished aluminum components -

Sheet metal bending plus spray powder

Sheet metal bending plus spray powder -

Black POM cnc machining service

Black POM cnc machining service -

Anodized aluminum plus silk screen

Anodized aluminum plus silk screen -

Rubber 3d printing earphone

Rubber 3d printing earphone -

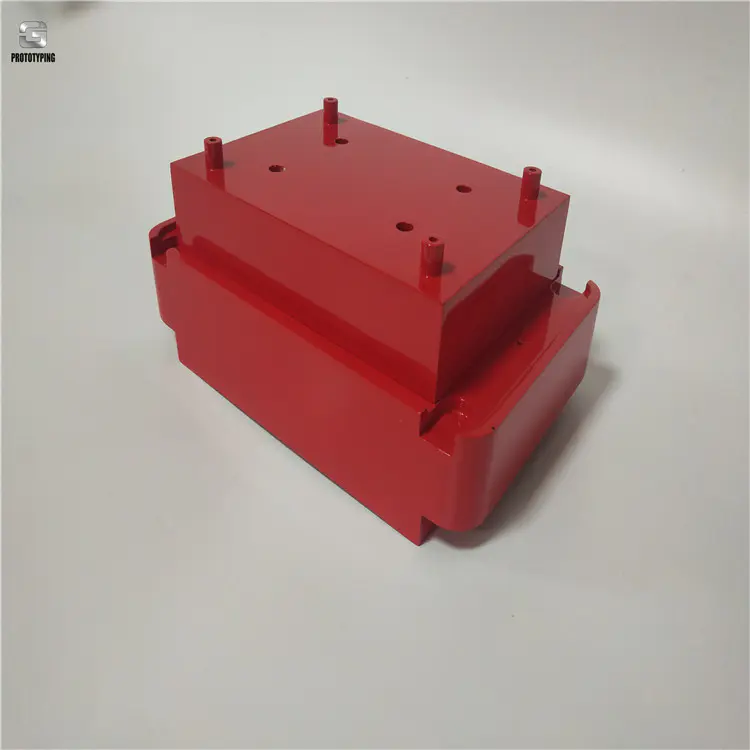

Glossy red paint components

Glossy red paint components -

3d printing electronic model

3d printing electronic model -

Nylon CNC machining

Nylon CNC machining -

Maple wood cnc machining

Maple wood cnc machining -

Glossy Coffee cup model

Glossy Coffee cup model -

Speaker model plus rubber paint

Speaker model plus rubber paint -

UV glossy robot components

UV glossy robot components -

High polished Stainless Steel 316L

High polished Stainless Steel 316L -

Electric fan with ABS matt painting

-

Walnut Chinese Tea Set

Walnut Chinese Tea Set -

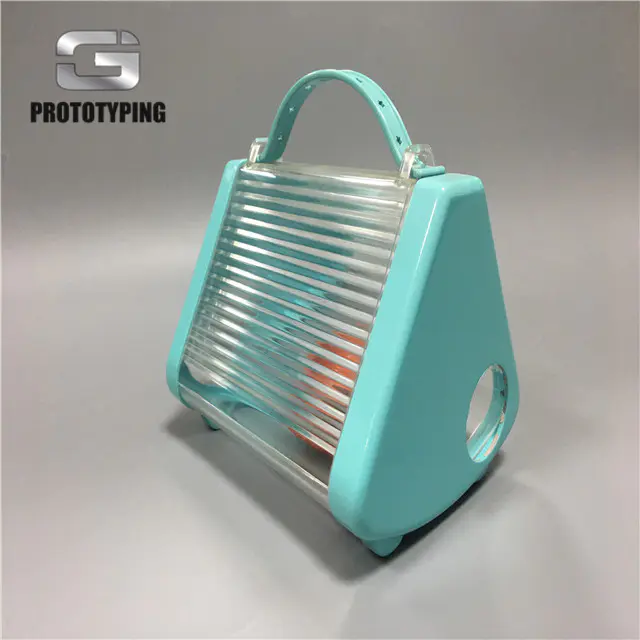

Acrylic Ladies Handbag

-

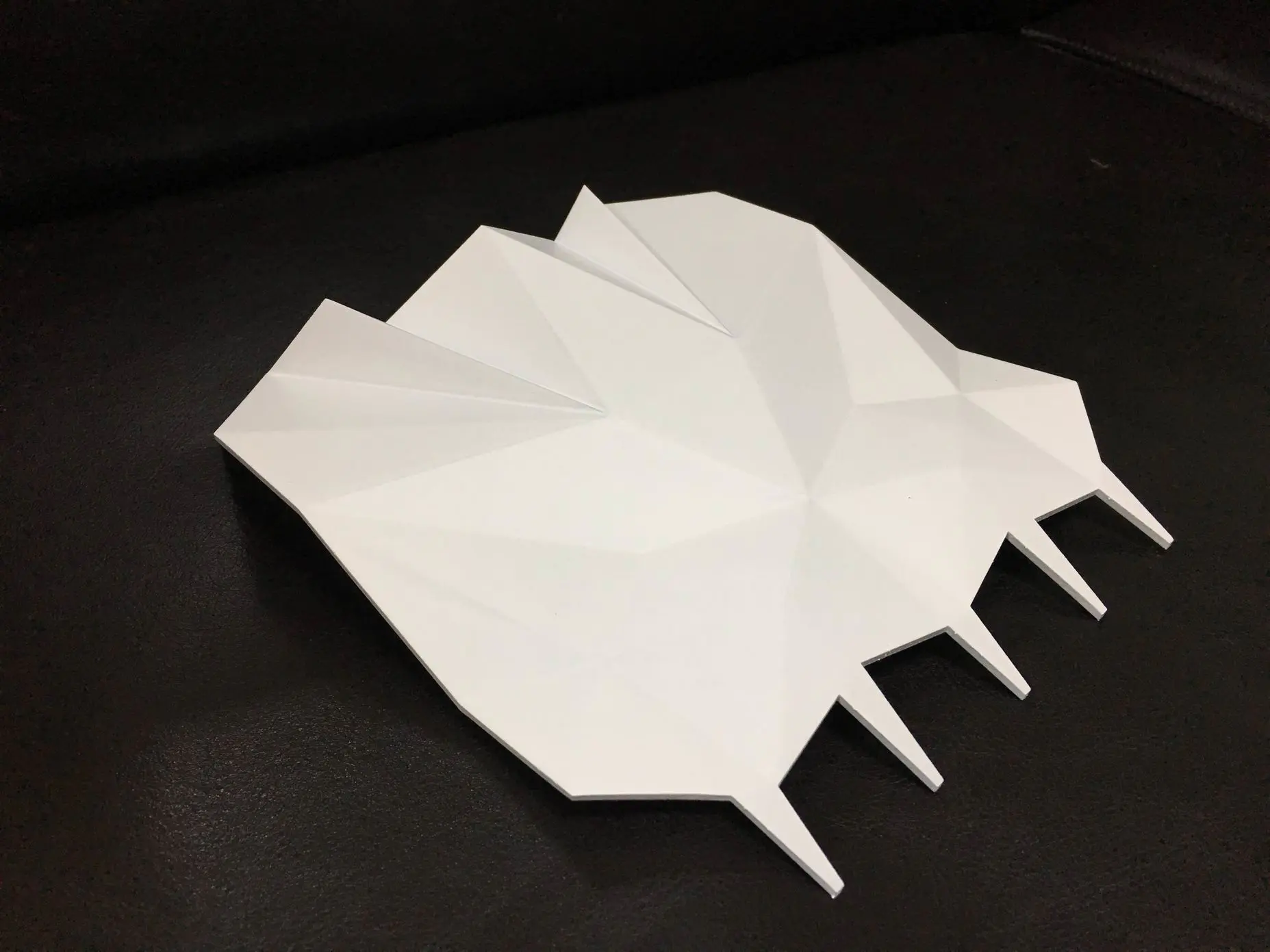

SLA Ice Skates

-

SLA glossy household electric kettle

SLA glossy household electric kettle -

Art tree SLA technology with red matt painting

Art tree SLA technology with red matt painting -

Polished brass by CNC machining

Polished brass by CNC machining -

Vaccum casting with matt painting ABS brass material

Vaccum casting with matt painting ABS brass material -

Transparent complex acrylic high polished box surface

Transparent complex acrylic high polished box surface -

Round silicone rubber plus middle ABS glossy paint

Round silicone rubber plus middle ABS glossy paint -

New design dresser total made by ABS plus Pantone code

New design dresser total made by ABS plus Pantone code -

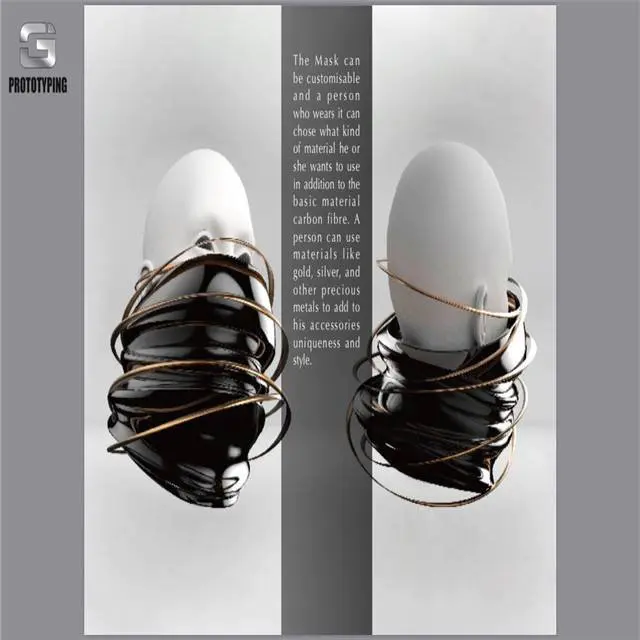

Mask made by SLA for kids or party

Mask made by SLA for kids or party -

SLA small components plus customized silk screen technology

SLA small components plus customized silk screen technology -

Glossy painted mask with ABS 3d printing

Glossy painted mask with ABS 3d printing -

3d printing children toy

-

Biotechnology art SLA 3d printing

Biotechnology art SLA 3d printing -

Electroplating Faucet 3d printing model

Electroplating Faucet 3d printing model -

Matte painted polishing surface professional 3d printing service companies

Matte painted polishing surface professional 3d printing service companies -

Customized pc painted digitization device with tolerance ±0.1mm

Customized pc painted digitization device with tolerance ±0.1mm -

Electroplating 3d printing rapid prototyping tea set

Electroplating 3d printing rapid prototyping tea set -

Guangzhou sls prototyping 3d printing rapid prototyping services

Guangzhou sls prototyping 3d printing rapid prototyping services -

comb sla rapid prototyping

comb sla rapid prototyping -

resin gear 3d printing rapid prototyping

resin gear 3d printing rapid prototyping -

Matte painted abs cnc machining protoype

Matte painted abs cnc machining protoype -

Rapid prototyping rose gold anodizing aluminium cnc milling parts

Rapid prototyping rose gold anodizing aluminium cnc milling parts -

Guangzhou CNC machining aluminium parts with tolerance ±0.1mm

Guangzhou CNC machining aluminium parts with tolerance ±0.1mm -

Blue painted glossy cnc machining aluminium rapid prototyping parts

Blue painted glossy cnc machining aluminium rapid prototyping parts -

High glossy blue anodizing precision precis ion cnc machining rapid prototyping china

High glossy blue anodizing precision precis ion cnc machining rapid prototyping china -

large size abs cnc plastic machining rapid prototyping companies

large size abs cnc plastic machining rapid prototyping companies -

3d printing plastic rapid prototyping making companies

-

Transparent high glossy 3d printing rapid prototyping making companies

Transparent high glossy 3d printing rapid prototyping making companies -

3d PC precision polishing plastic cnc machining prototyping companies

3d PC precision polishing plastic cnc machining prototyping companies -

abs plastic machining parts for medical devive

abs plastic machining parts for medical devive -

Fully transparent PMMA cnc plastic machining parts company

Fully transparent PMMA cnc plastic machining parts company -

acrylic plastic high transparency cnc precision machining parts for laboratory testing

acrylic plastic high transparency cnc precision machining parts for laboratory testing -

fully transparent pmma plastic china cnc machining service

fully transparent pmma plastic china cnc machining service -

Glossy painted resin 3d printing rapid prototyping services

Glossy painted resin 3d printing rapid prototyping services -

Guangzhou painted 3d printing rapid prototyping services

Guangzhou painted 3d printing rapid prototyping services -

silicon vacuum casting process in rapid prototyping

-

white nylon with glassfiber 3d printing service companies

white nylon with glassfiber 3d printing service companies -

Nylon low volume vacuum casting prototype companies

Nylon low volume vacuum casting prototype companies -

wood cnc machining services china for shoes heel

wood cnc machining services china for shoes heel -

sla 3d printing rapid prototyping companies

sla 3d printing rapid prototyping companies -

3d aluminium metal rapid prototyping parts

3d aluminium metal rapid prototyping parts -

Transparent acrylic cnc machining service

Transparent acrylic cnc machining service