How is vacuum casting prototyping working?And why you choose this process from us?

Email: gj-model@hotmail.com

More info. pls visit: www.gj-prototype.com

WHAT IS VACUUM CASTING?

Vacuum casting involves making a mold out of silicone rubber, usually based upon a master model created by CNC machining or one of our rapid prototyping services.

VACUUM CASTING

We made a master model using stereolithography (SLA), a 3D printing technology.The main pattern can be any solid material, they are excellent candidates, 3D printing plastic such as SLA, SLS. main mode need to be carefully done, because the silicon die to do a good job, even tiny details surface transfer to any subsequent copies.

MATERIALS

Hundreds of casting polymers are commercially available to reproduce any conceivable hardness and surface texture. It is also possible to make parts that are fully opaque, translucent or completely transparent depending on your application. See more information on available materials.

We made a silicon mold according to the template to form a master pattern using the customer's 3D product design. Once the master mold was created we could start the vacuum casting replica.The typical mold is a good high fidelity replica of around twenty, ideal for rapid prototyping with minimal cost.

Machining Services

Material Capabilities: ABS, POM, PP, PC, PE, PA(Nylon), PC+GF,Resin,Silicone and etc

Color: can be customized

MOQ: 1 piece

Files format: .IGS .STP .STL .X-T

Surface treatment: Polish, Painting, Silk-printing, UV coating, Electroplating,etc

Business type: OEM manufacturer

Vacuum complex mode refers to the use of the existing prototype, through making a silicone mold, using silicone mode under vacuum pouring liquid resin, copy the prototype.Because there are so many types of liquid resin, performance is different, so can through this method to obtain all kinds of products with different properties of the material.

Applianction Cases: Car prototype,Architecture model ,Automotive, Automation, Test systems, Sensors, Medical,Sports,Consumer, Home appliance, Electronic , Pumps, Computers, Power and energy, Architecture,Printing,Food ,Textile ,Furniture,Commodity,Electronic etcmachinery,Optical,Lighting, Security and safety, AOI, SMT equipment, etc.

Why you choose this process from us?

1.The mold can be use for copy 100- 200 times, when you pay the cost for opening the mold for the few sample ,after your test, if you want to copy more quantity later , the mold can be reserved in our factory will not charge extra fee.

2.For the rubber part ,it can custom the shore from 35-65 °

3.Both rubber and the plastic material color can be customized.

4. Transparent material like Acrylic and PC can be used in this process, and the semi transparent rubber is also available.

ADVANTAGES OF VACUUM CASTING:

Vacuum casting is an ideal choice for rapid prototyping because:

1.There is a low initial cost since it doesn’t require investment in tooling;

2.The high fidelity of the mold gives excellent surface details requiring little or no post-processing;

3.Many different molding polymers are available that can be pigmented to meet your color requirements;

4.Molds can be ready in a few days once the master model has been created;

5.Molds are durable up to approximately 50 copies so it’s great if you need more than one copy;

6.We provide overmolding, so that different types and hardnesses of plastic can be molded together into a single unit;

7.It is an excellent option for testing multiple variations of a prototype design for rapid product development.

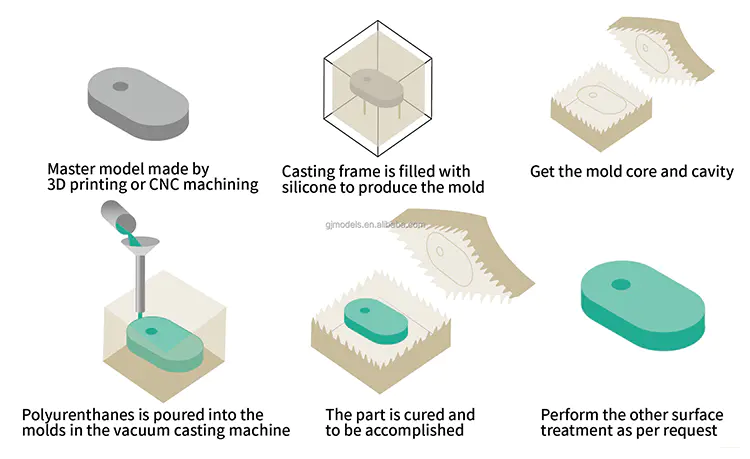

VACUUM CASTING PROCESS:

Stage One: Making the Master Mold

1, A solid master model or pattern is required. This can be made of any stable material, and can either be supplied by you or alternately created by Gaojie Model using our 3D printing services or via CNC machining.

2, Typically master patterns are made in plastic or metal, the only requirement being that they are able to withstand a temperature of 40° C for an extended period of curing.

3, We then suspend this pattern inside of a casting box, which we half-fill with liquid silicone rubber. This is placed inside of a curing oven and heated at 40° C until the silicone is fully cured.

4, The casting box is then filled with additional silicone liquid which is also heated and cured. The two halves are treated with a releasing agent for later separation.

5, Once fully cured, the silicone rubber mold is opened up along the parting line and the original master removed.

STAGE Two: MAKING THE PARTS

1, During mold making, our craftsmen strategically place a series of fine holes surrounding the master pattern. These holes will be used to later draw air pressure out of the mold.

2, Once the master has been removed, there is now a hollow cavity in the silicone mold which is an exact reverse image of the original.

3, We can fill this cavity with any number of molding polymers to suit your design requirements. Once the cavity is filled, it’s placed into a vacuum chamber which draws air out of the cavity and pulls the liquid plastic into all of the recesses of the mold, ensuring an exact conformity to the original shape.

4, Finally the mold goes into a curing oven one more time, creating a solid and stable replica of your original master pattern.

TOLERANCES

The finished dimensions of vacuum cast parts is dependent on the accuracy of the master model, part geometry and casting material. In general, a shrinkage rate of 0.15% is to be expected.

ARE YOU READY TO START YOUR NEXT PROJECT?

We’re proud to say that our vacuum cast parts have helped to pave the way towards full-scale production on many successful and famous products used in commercial, industrial and scientific applications around the world. We’re confident we can meet and exceed your expectations just as we’ve done for thousands of customers before. Contact us today for a free design review and quotation.

-

How is vacuum casting prototyping working?And why you choose this process from us?

How is vacuum casting prototyping working?And why you choose this process from us? -

SLA 3D Printed Chinese Dragon

SLA 3D Printed Chinese Dragon -

custom 3d printing service sla/sls printing processing introduction

custom 3d printing service sla/sls printing processing introduction -

High quality Prototyping China - Rapid Prototyping 3D Printing

High quality Prototyping China - Rapid Prototyping 3D Printing -

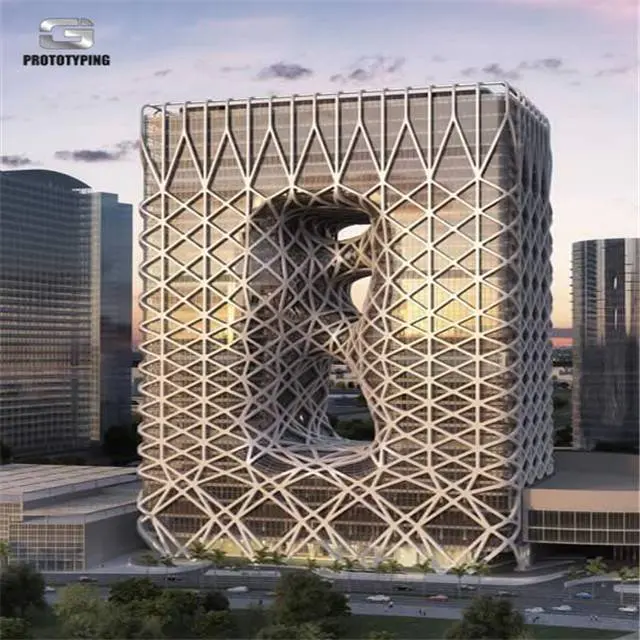

Zaha hadid design -- Morpheus Hotel in Macau

Zaha hadid design -- Morpheus Hotel in Macau -

Scent bottle by transparent PMMA plus electroplating top cap

-

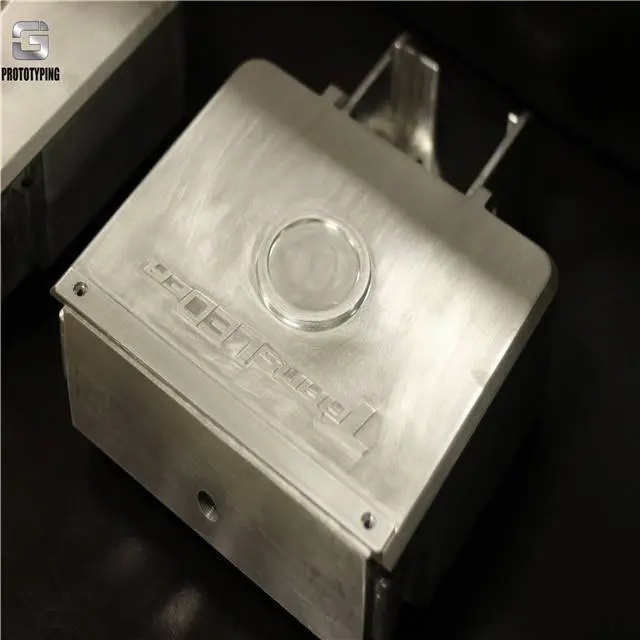

High polished surface aluminum components

High polished surface aluminum components -

Transparent acrylic box used with cnc machining milling service

Transparent acrylic box used with cnc machining milling service -

High Polished Aluminum 6061 by CNC machining

High Polished Aluminum 6061 by CNC machining -

Aluminum 6061 boxes plus LOGO CNC machining

Aluminum 6061 boxes plus LOGO CNC machining -

Stainless Steel 304 CNC machining +-0.1mm

Stainless Steel 304 CNC machining +-0.1mm -

Polished brass components by CNC machining

Polished brass components by CNC machining -

CNC milling machining service andanodized color aluminum 6061 6063 box

CNC milling machining service andanodized color aluminum 6061 6063 box -

Polished brass keyboard CNC machining

Polished brass keyboard CNC machining -

Aluminum 6061 shoes model

Aluminum 6061 shoes model -

Matt black car components

Matt black car components -

High polished aluminum components

High polished aluminum components -

Sheet metal bending plus spray powder

Sheet metal bending plus spray powder -

Black POM cnc machining service

Black POM cnc machining service -

Anodized aluminum plus silk screen

Anodized aluminum plus silk screen -

Rubber 3d printing earphone

Rubber 3d printing earphone -

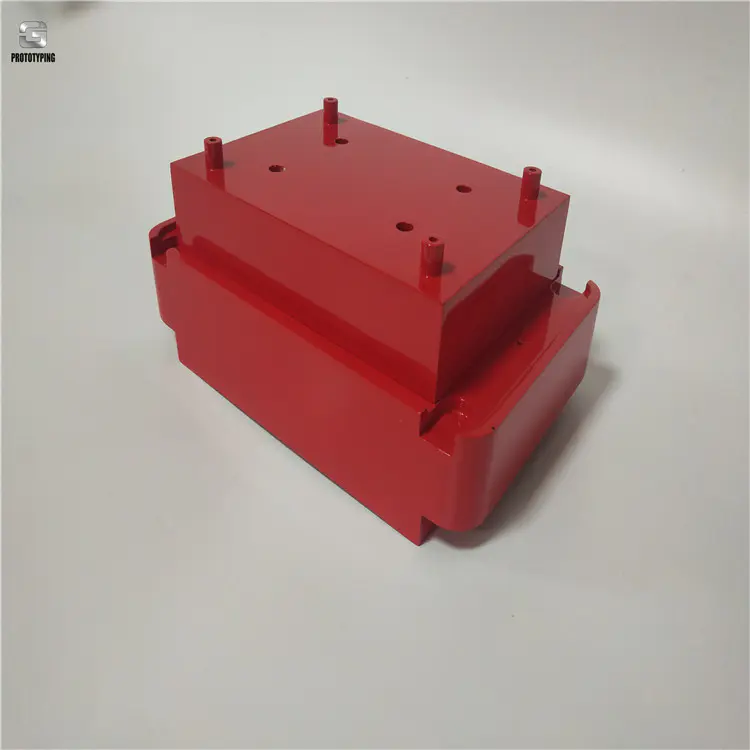

Glossy red paint components

Glossy red paint components -

3d printing electronic model

3d printing electronic model -

Nylon CNC machining

Nylon CNC machining -

Maple wood cnc machining

Maple wood cnc machining -

Glossy Coffee cup model

Glossy Coffee cup model -

Speaker model plus rubber paint

Speaker model plus rubber paint -

UV glossy robot components

UV glossy robot components -

High polished Stainless Steel 316L

High polished Stainless Steel 316L -

Electric fan with ABS matt painting

-

Walnut Chinese Tea Set

Walnut Chinese Tea Set -

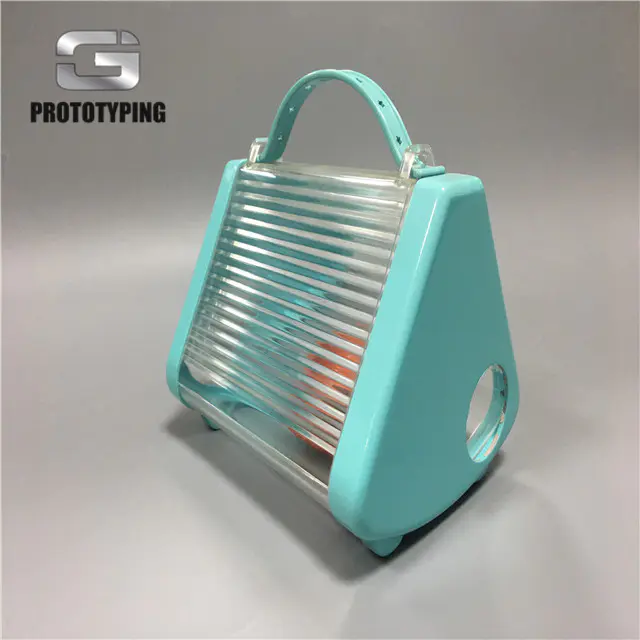

Acrylic Ladies Handbag

-

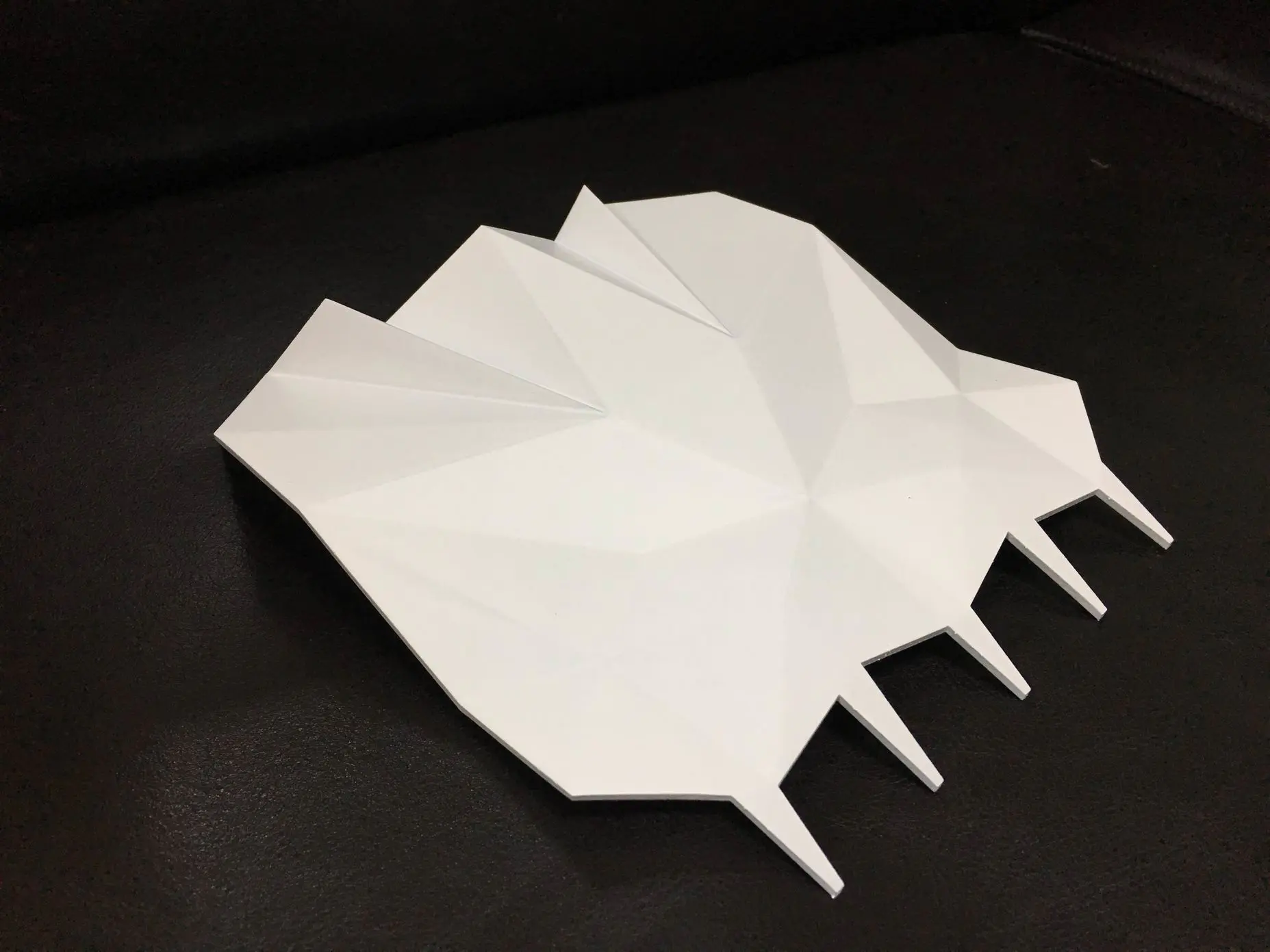

SLA Ice Skates

-

SLA glossy household electric kettle

SLA glossy household electric kettle -

Art tree SLA technology with red matt painting

Art tree SLA technology with red matt painting -

Polished brass by CNC machining

Polished brass by CNC machining -

Vaccum casting with matt painting ABS brass material

Vaccum casting with matt painting ABS brass material -

Transparent complex acrylic high polished box surface

Transparent complex acrylic high polished box surface -

Round silicone rubber plus middle ABS glossy paint

Round silicone rubber plus middle ABS glossy paint -

New design dresser total made by ABS plus Pantone code

New design dresser total made by ABS plus Pantone code -

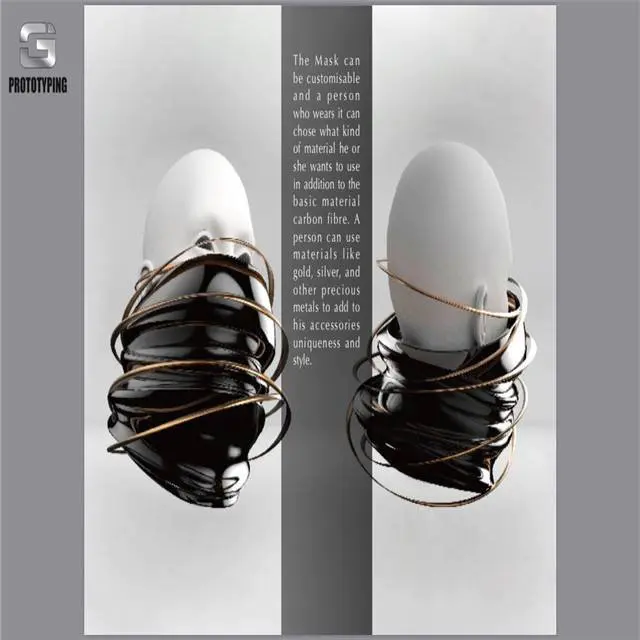

Mask made by SLA for kids or party

Mask made by SLA for kids or party -

SLA small components plus customized silk screen technology

SLA small components plus customized silk screen technology -

Glossy painted mask with ABS 3d printing

Glossy painted mask with ABS 3d printing -

3d printing children toy

-

Biotechnology art SLA 3d printing

Biotechnology art SLA 3d printing -

Electroplating Faucet 3d printing model

Electroplating Faucet 3d printing model -

Matte painted polishing surface professional 3d printing service companies

Matte painted polishing surface professional 3d printing service companies -

Customized pc painted digitization device with tolerance ±0.1mm

Customized pc painted digitization device with tolerance ±0.1mm -

Electroplating 3d printing rapid prototyping tea set

Electroplating 3d printing rapid prototyping tea set -

Guangzhou sls prototyping 3d printing rapid prototyping services

Guangzhou sls prototyping 3d printing rapid prototyping services -

comb sla rapid prototyping

comb sla rapid prototyping -

resin gear 3d printing rapid prototyping

resin gear 3d printing rapid prototyping -

Matte painted abs cnc machining protoype

Matte painted abs cnc machining protoype -

Rapid prototyping rose gold anodizing aluminium cnc milling parts

Rapid prototyping rose gold anodizing aluminium cnc milling parts -

Guangzhou CNC machining aluminium parts with tolerance ±0.1mm

Guangzhou CNC machining aluminium parts with tolerance ±0.1mm -

Blue painted glossy cnc machining aluminium rapid prototyping parts

Blue painted glossy cnc machining aluminium rapid prototyping parts -

High glossy blue anodizing precision precis ion cnc machining rapid prototyping china

High glossy blue anodizing precision precis ion cnc machining rapid prototyping china -

large size abs cnc plastic machining rapid prototyping companies

large size abs cnc plastic machining rapid prototyping companies -

3d printing plastic rapid prototyping making companies

-

Transparent high glossy 3d printing rapid prototyping making companies

Transparent high glossy 3d printing rapid prototyping making companies -

3d PC precision polishing plastic cnc machining prototyping companies

3d PC precision polishing plastic cnc machining prototyping companies -

abs plastic machining parts for medical devive

abs plastic machining parts for medical devive -

Fully transparent PMMA cnc plastic machining parts company

Fully transparent PMMA cnc plastic machining parts company -

acrylic plastic high transparency cnc precision machining parts for laboratory testing

acrylic plastic high transparency cnc precision machining parts for laboratory testing -

fully transparent pmma plastic china cnc machining service

fully transparent pmma plastic china cnc machining service -

Glossy painted resin 3d printing rapid prototyping services

Glossy painted resin 3d printing rapid prototyping services -

Guangzhou painted 3d printing rapid prototyping services

Guangzhou painted 3d printing rapid prototyping services -

silicon vacuum casting process in rapid prototyping

-

white nylon with glassfiber 3d printing service companies

white nylon with glassfiber 3d printing service companies -

Nylon low volume vacuum casting prototype companies

Nylon low volume vacuum casting prototype companies -

wood cnc machining services china for shoes heel

wood cnc machining services china for shoes heel -

sla 3d printing rapid prototyping companies

sla 3d printing rapid prototyping companies -

3d aluminium metal rapid prototyping parts

3d aluminium metal rapid prototyping parts -

Transparent acrylic cnc machining service

Transparent acrylic cnc machining service