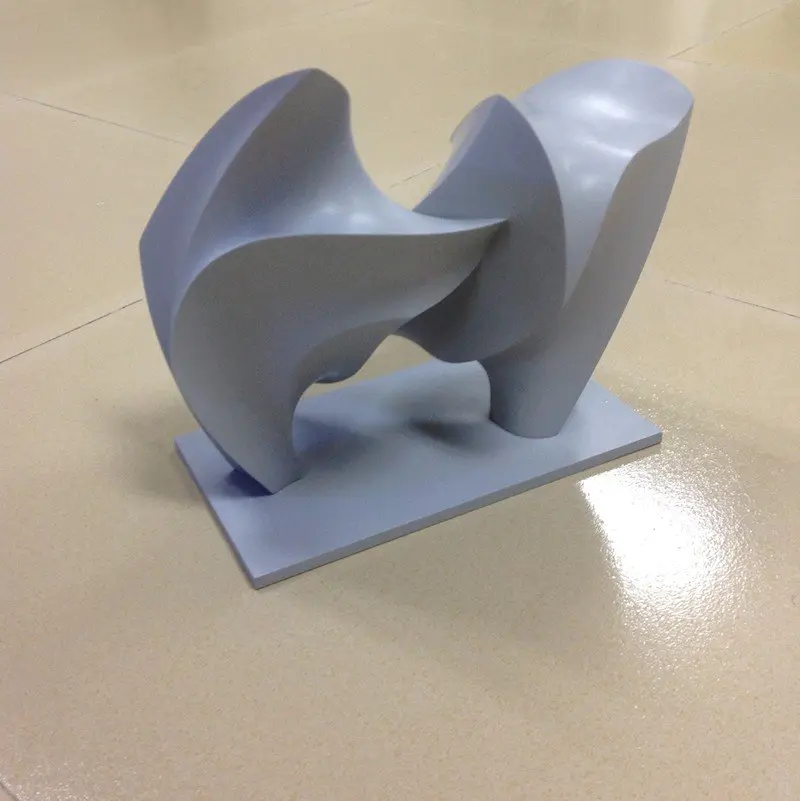

What are applications of 3d printing metal parts produced by Gaojie?

2019-10-07

Guangzhou Gaojie Model Design & Manufacture Co., Ltd., as a brand company, has been involving the business in a majority of industrial fields. 3d printing metal parts , as one of the main products promoted by our company's research & development department, is the one that the company has vested most of our trust in it. According to our exception, this kind of product can be applied to some common aspects of our daily life, and it can also be used to some specified aspects to highlight its function. And its application shall be determined by the detail situation and customers’ demand. There is no doubt all of its application can present its advanced technology and multifunction.

Gaojie, widely known as a credible China-based manufacturing company, has a strong ability in developing and producing metal rapid prototyping. 3d printing companies produced by Gaojie is very popular in the market. Gaojie Model 3d printing companies is designed to meet customer's unique individual style. At we Model, hundreds of casting polymers are commercially available to reproduce any conceivable hardness and surface texture out of silicone molding casting. The test shows that vacuum casting can enable rapid prototyping companies and is easy to operate and maintain. Anodizing improves corrosion protection, surface hardness, wear resistance, aesthetic appearance and the adhesion of paints and primers. we is very professional in giving anodizing treatment to different materials for prototyping process.

With the support of our professionals, our team Model has enough confidence to make custom plastic fabrication. Get more info!

Gaojie, widely known as a credible China-based manufacturing company, has a strong ability in developing and producing metal rapid prototyping. 3d printing companies produced by Gaojie is very popular in the market. Gaojie Model 3d printing companies is designed to meet customer's unique individual style. At we Model, hundreds of casting polymers are commercially available to reproduce any conceivable hardness and surface texture out of silicone molding casting. The test shows that vacuum casting can enable rapid prototyping companies and is easy to operate and maintain. Anodizing improves corrosion protection, surface hardness, wear resistance, aesthetic appearance and the adhesion of paints and primers. we is very professional in giving anodizing treatment to different materials for prototyping process.

With the support of our professionals, our team Model has enough confidence to make custom plastic fabrication. Get more info!

Custom message