1.Design Your Prototype:

Use 3D modeling software (such as AutoCAD, SolidWorks, or Blender) to create a digital 3D model of your prototype. Ensure that your design is suitable for the SLS printing process.

2.File Preparation:

Save your 3D model in a file format that is compatible with the SLS 3D printer. Common formats include STL (Standard Triangle Language) and OBJ (Wavefront Object).

3.Pre-Processing:

Some 3D printing software or online services provide pre-processing tools. These tools may include features for orienting, scaling, and adding support structures to your model.

4.Material Selection:

Choose the appropriate SLS printing material. SLS commonly uses powdered nylon, but other materials like glass-filled nylon, TPU, and more may be available. The material choice depends on the properties you need in your prototype.

5.SLS Printing:

Submit your 3D model to an SLS 3D printer. The printer will follow the digital model's instructions to selectively sinter layers of powdered material, building up the prototype.

6.Cooling:

After each layer is sintered, it's allowed to cool before the next layer is added. This helps ensure that the layers fuse correctly and maintain structural integrity.

7.Post-Processing:

Once the printing is complete, the prototype may need to undergo post-processing. This can involve removing excess powder, cleaning the part, and possibly surface finishing or treating it depending on your requirements.

8.Inspection and Testing:

Inspect the printed prototype for quality and accuracy. Test its functionality if applicable.

9.Iterate if Necessary:

If the prototype doesn't meet your expectations, you may need to go back to the design stage and make necessary adjustments. This iterative process is common in product development.

10.Documentation:

Keep detailed documentation of your prototype, including design files, printing parameters, and any post-processing steps. This information is valuable for future reference or for reproducing the prototype.

Nylon Printing Material Properties: Nylon is a versatile thermoplastic known for its strength, flexibility, and resistance to wear and tear.

Applications:Commonly used for functional prototypes, end-use parts, and products that require a balance of strength and flexibility.

PA6 (Polyamide 6), PA66 (Polyamide 66), and PA12 (Polyamide 12) are all types of nylon, which is a class of polymers known as polyamides. They have differences in their molecular structures, properties, and applications. Here's a summary of the distinctions:

1.Molecular Structure:

PA6: Composed of repeating units of 6 carbon atoms.

PA66: Composed of repeating units of 6 carbon atoms and 6 nitrogen atoms.

PA12: Composed of repeating units of 12 carbon atoms.

2.Melting Point:

PA6: Typically has a melting point in the range of 215-225 degrees Celsius.

PA66: Generally has a higher melting point, around 260-270 degrees Celsius.

PA12: Has a lower melting point compared to PA6 and PA66.

3.Mechanical Properties:

PA6: Exhibits good toughness and impact resistance. It has lower strength and stiffness compared to PA66.

PA66: Known for higher strength, stiffness, and better heat resistance compared to PA6.

PA12: Often possesses good impact resistance and flexibility, making it suitable for certain applications.

4.Water Absorption:

PA6: Tends to absorb more moisture compared to PA66 and PA12. The absorption of moisture can affect its mechanical properties.

PA66: Exhibits lower water absorption than PA6.

PA12: Generally has lower water absorption compared to both PA6 and PA66.

5.Thermal Stability:

PA6: Shows good thermal stability, but it may be lower compared to PA66.

PA66: Offers better thermal stability, making it suitable for applications requiring high-temperature resistance.

PA12: Has moderate thermal stability.

6.Applications:

PA6: Commonly used in automotive parts, consumer goods, and various industrial applications.

PA66: Widely used in automotive components, electrical and electronic parts, and structural components requiring high mechanical strength.

PA12: Often utilized in applications such as flexible tubing, oil and gas pipes, and certain automotive components.

The choice between PA6, PA66, and PA12 depends on the specific requirements of the application, including mechanical properties, thermal resistance, water absorption, and cost considerations. Each type of nylon has its advantages and is selected based on the desired performance characteristics for a given application.

| Quotation | According to your drawing(size, material, thickness, processing content and required technology, etc.) |

| Available Service | 1.Design |

| 2. CNC Rapid Prototyping | |

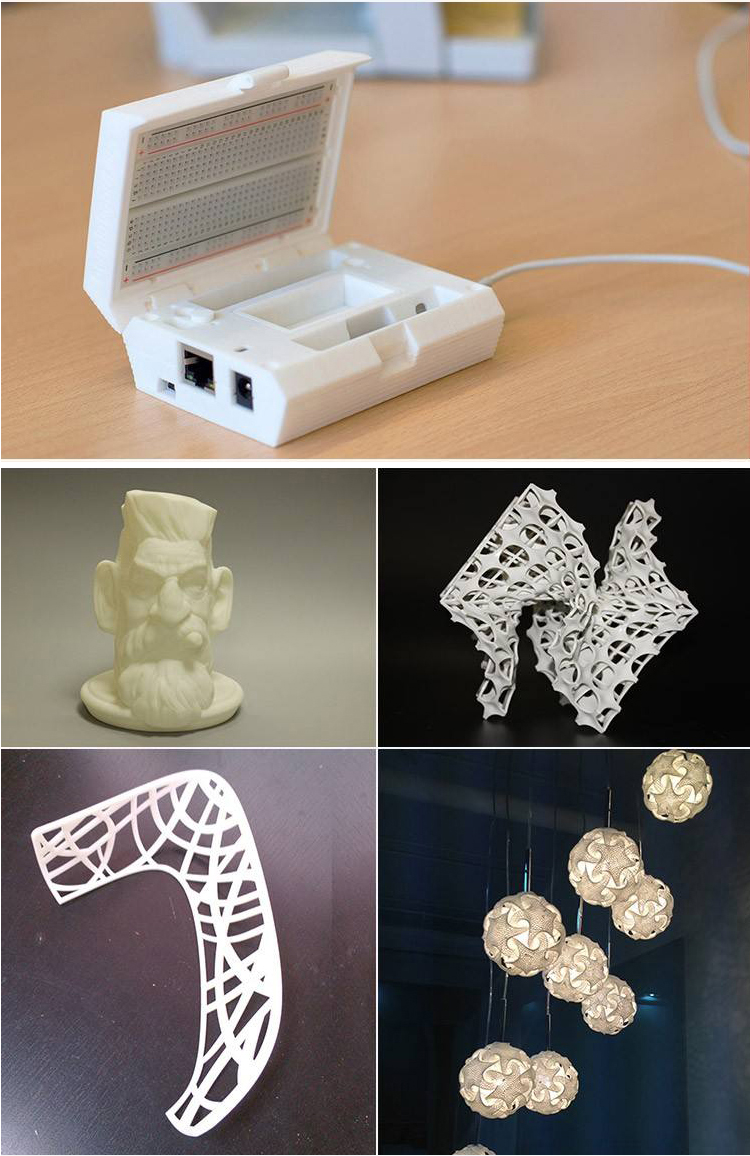

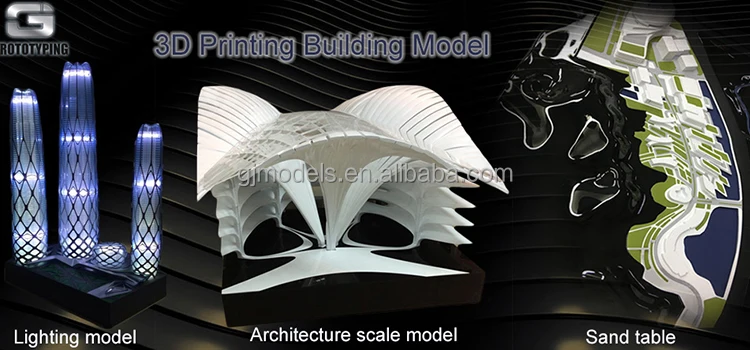

| 3. SLS/SLA/3D Printing Prototype Service | |

| 4. High Precision CNC Machining | |

| 5. Silicone Mold (Vacuum Casting) & Rapid Tooling | |

| Material | Aluminum(6061,6063,mic6), stainless steel,brass,ABS,PC,POM, PP, PE, PA(Nylon),acrylic,wood,carbon fiber,copper, etc |

| Surface treatment | Polished, High polishing, Anodizing, Painting, Electroplating, Laser Engraving, Sand blasting, Brushed etc |

Our services include SLA, SLS, vacuum casting, CNC machining, rapid prototype, small batches prototypes, company is equipped with SLA,SLS, CNC machining center, CNC engraving and milling machine,lathe, milling machine, Vacuum Casting Machine and other rapid prototyping equipments

Q1.What is the material?

A1.Plastics we can manufacture are ABS, PC,PMMA, PP, PA, PA+GF, PTFE etc, metals are aluminum, stainless steel, brass, copper etc.

EPOS Decision Vislon Enclosure Prototype,Mechanics Diagnostic Enclosure Prototype,Paint Thickness Gauge Enclosure Prototype,Medical Camera Enclosure Prototype,In Flight Entertanment Enclosure Prototype,Professional Navigation Enclosure Prototype,Data Logger Enclosure Prototype,Handheld Enclosure Prototype,Comms Enclosure Prototype,

EPOS Display Enclosure Prototype,Podd Enclosure Prototype,Medical Diagnostics Enclosure Prototype,Taxi Enclosure Prototype,Casino Display Enclosure Prototype,Thermo Scientific Enclosure Prototype,Taxi Meter Enclosure Prototype,Gas Detector Kit Enclosure Prototype,Police Handheld Enclosure Prototype,Robot Enclosure Prototype,Digital Camera Enclosure Prototype

Copyright © 2025 Design by Gaojie Model | Sitemap