Company Advantages1. silicone mold making service materials ensure vacuum casting get high performance.

2. The design of the product is eye-catching. It aims to let the packaged items being noticed by the customers.

3. The product is gradually recognized by the majority of customers.

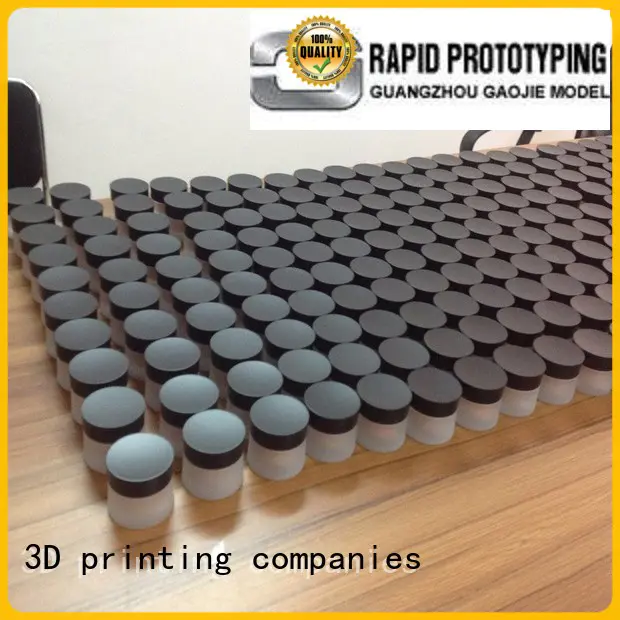

3D Printing The Model

We made a master model using stereolithography (SLA), a 3D printing technology.The main pattern can be any solid material, they are excellent candidates, 3D printing plastic such as SLA, SLS. main mode need to be carefully

done, because the silicon die to do a good job, even tiny details surface transfer to any subsequent copies.

Making the mold

We made a silicon mold according to the template to form a master pattern using the customer's 3D product design. Once the master mold was created we could start the vacuum casting replica.The typical mold is a good high

fidelity replica of around twenty, ideal for rapid prototyping with minimal cost.

Type:Other Machining Services

Material Capabilities: ABS, POM, PP, PC, PE, PA(Nylon), PC+GF,Resin,Silicone and etc

Color: can be customized

MOQ: 1 piece

Files format: .IGS .STP .STL .X-T

Surface treatment: Polish, Painting, Silk-printing, UV coating, Electroplating,etc

Business type: OEM manufacturer

Company Features1. As a wide-ranging company, Gaojie Model has been striving forward to achieve the combination of R&D, manufacture, sales and service of vacuum casting .

2. Gaojie Model has strong ability to produce prototype manufacturing.

3. The company will continue to take a variety of steps to reduce its environmental influence. These steps mainly include two parts: reducing greenhouse gases emission and limiting pollution. Get quote! To embrace sustainability, we measure our emissions performance, ensuring comprehensive tracking of our emissions using internal sustainability software. Since we adopted a strict waste management plan, the waste amount has decreased significantly. This plan covers several aspects, including resources utilizing strategy, the limitation of discharge, and waste utilization. Get quote!