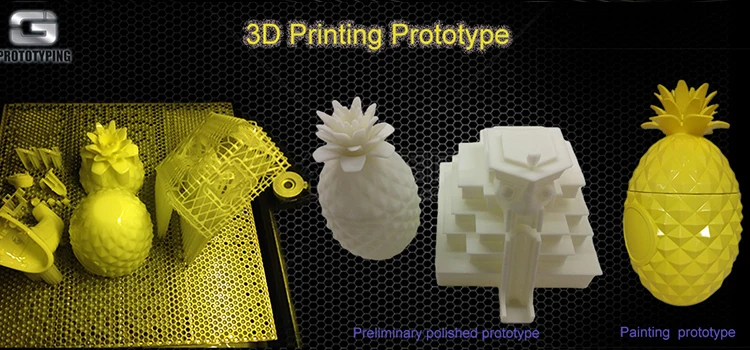

High precision sla 3d printing service and 3d model rapid prototypes factory maker

Gaojie-model Rapid Prototyping:

Rapid prototyping refers to the quick fabrication of a physical model or prototype for testing, evaluation, and iteration. 3D printing, especially technologies like SLA, is commonly used for rapid prototyping due to its speed and precision.

Gaojie-Model 3D Printing Service:

Many companies offer 3D printing services where you can submit your 3D model, and they will manufacture the physical object for you. This is useful if you don't have access to a 3D printer or if you need a high-quality prototype.

What‘s SLA 3D printing ?

Stereolithography – more commonly referred to as SLA 3D printing – is one of the most popular and widespread techniques in the world of additive manufacturing. It works by using a high-powered laser to harden liquid resin that is contained in a reservoir to create the desired 3D shape. In a nutshell, this process converts photosensitive liquid into 3D solid plastics in a layer by-layer fashion using a low power laser and photopolymerization.

Every standard SLA 3D printer is generally composed of four primary sections:

* A tank filled with the liquid photopolymer: The liquid resin is usually a clear and liquid plastic.

* A perforated platform immersed in a tank: The platform is lowered into the tank and can move up and down according to the printing process.

* A high-powered, ultraviolet laser.

* A computer interface, which manages both the platform and the laser movements.

SLA 3D Printing Advantages:

* SLA is one of the most precise 3D printing techniques on the market.

* Prototypes can be created with extremely high quality, with finely detailed features (thin walls, sharp corners, etc…) and complex geometrical shapes. Layer thicknesses can be made as low as 25 μm, with minimum feature sizes between 50 and 250 μm.

* Print surfaces are smooth.

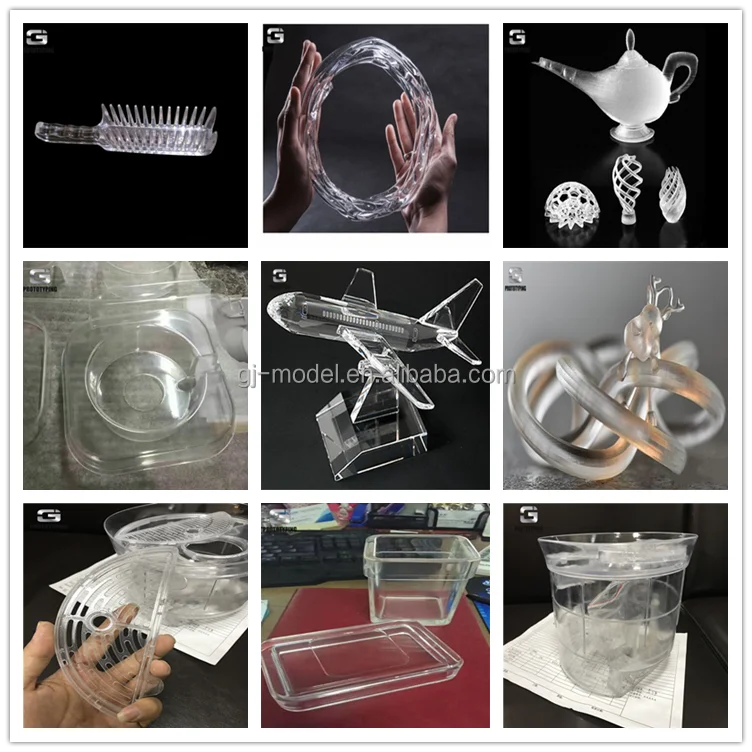

Gaojie-model Transparent Resin Printing:

Transparent resins are used in 3D printing to create parts and prototypes that have a transparent or translucent appearance. This is particularly useful for applications where visual clarity or light transmission is important.

If you are looking for a specific 3D printing service that provides SLA 3D printing with transparent resin for rapid prototyping, you can contact us.

1.Design Your Prototype:

Use 3D modeling software (such as AutoCAD, SolidWorks, or Blender) to create a digital 3D model of your prototype. Ensure that your design is suitable for the SLS printing process.

2.File Preparation: Save your 3D model in a file format that is compatible with the SLS 3D printer. Common formats include STL (Standard Triangle Language) and OBJ (Wavefront Object).

3.Pre-Processing: Some 3D printing software or online services provide pre-processing tools. These tools may include features for orienting, scaling, and adding support structures to your model.

4.Material Selection: Choose the appropriate SLS printing material. SLS commonly uses powdered nylon, but other materials like glass-filled nylon, TPU, and more may be available. The material choice depends on the properties you need in your prototype.

5.SLS Printing: Submit your 3D model to an SLS 3D printer. The printer will follow the digital model's instructions to selectively sinter layers of powdered material, building up the prototype.

6.Cooling: After each layer is sintered, it's allowed to cool before the next layer is added. This helps ensure that the layers fuse correctly and maintain structural integrity.

7.Post-Processing: Once the printing is complete, the prototype may need to undergo post-processing. This can involve removing excess powder, cleaning the part, and possibly surface finishing or treating it depending on your requirements.

8.Inspection and Testing: Inspect the printed prototype for quality and accuracy. Test its functionality if applicable.

9.Iterate if Necessary: If the prototype doesn't meet your expectations, you may need to go back to the design stage and make necessary adjustments. This iterative process is common in product development.

10.Documentation: Keep detailed documentation of your prototype, including design files, printing parameters, and any post-processing steps. This information is valuable for future reference or for reproducing the prototype.

| Quotation | According to your drawing(size, material, thickness, processing content and required technology, etc.) |

| Available Service | 1.Design |

| 2. CNC Rapid Prototyping | |

| 3. SLS/SLA/3D Printing Prototype Service | |

| 4. High Precision CNC Machining | |

| 5. Silicone Mold (Vacuum Casting) & Rapid Tooling | |

| Surface treatment | Polished, High polishing, Anodizing, Painting, Electroplating, Laser Engraving, Sand blasting, Brushed etc |

| Anodized colors | Do as pantone,Accept customization |

Q1.What is the material?

A1.Plastics we can manufacture are ABS, PC,PMMA, PP, PA, PA+GF, POM,PTFE etc, metals are aluminum, stainless steel, brass, copper etc.

Copyright © 2025 Design by Gaojie Model | Sitemap