Selective Laser Sintering (SLS) is a 3D printing technology that uses a laser to selectively sinter (fuse) powdered material, typically nylon or other polymers, layer by layer, to create a three-dimensional object. If you're looking to create an SLS 3D printing prototype, here are the general steps you might follow:

1.Design Your Prototype: Use 3D modeling software to create a digital 3D model of your prototype.

2.File Preparation: Save your 3D model in a file format common formats include STLand OBJ .

3.Pre-Processing:Some 3D printing software or online services provide pre-processing tools. These tools may include features for orienting, scaling, and adding support structures to your model.

4.Material Selection: SLS commonly uses powdered nylon, but other materials choice depends on the properties you need in your prototype.

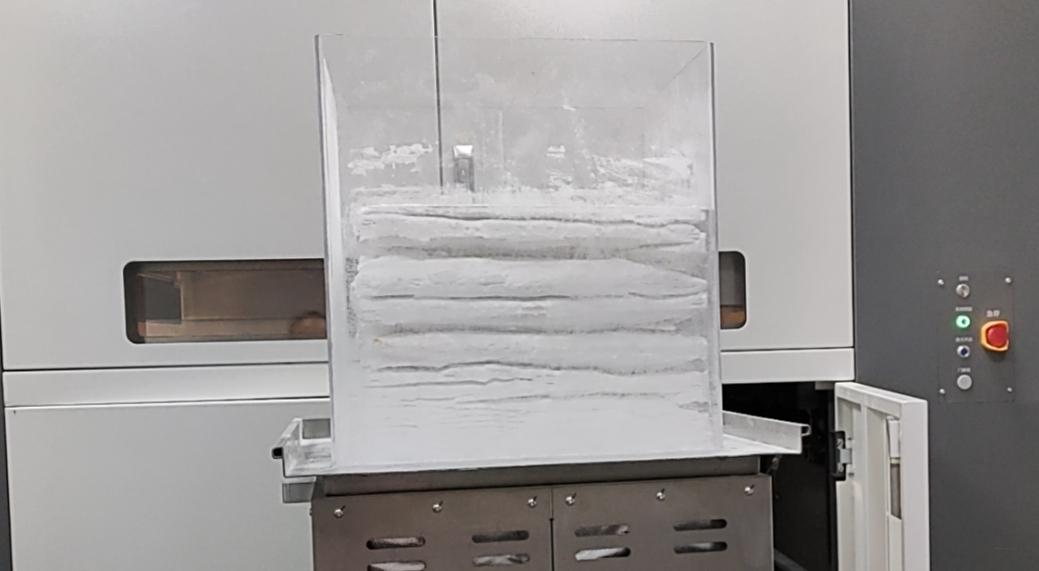

5.SLS Printing:The printer will follow the digital model's instructions to selectively sinter layers of powdered material,

building up the prototype.

6.Cooling: After each layer is sintered, it's allowed to cool before the next layer is added. This helps ensure that the layers fuse correctly and maintain structural integrity.

7.Post-Processing: Once the printing is complete, the prototype may need to undergo post-processing. This can involve removing excess powder, cleaning the part, and possibly surface finishing or treating it depending on your requirements.

8.Inspection and Testing: Inspect the printed prototype for quality and accuracy. Test its functionality if applicable.

9.Iterate if Necessary: If the prototype doesn't meet your expectations, you may need to go back to the design stage and make necessary adjustments. This iterative process is common in product development.

10.Documentation: Keep detailed documentation of your prototype, including design files, printing parameters, and any post-processing steps. This information is valuable for future reference or for reproducing the prototype.

Nylon Printing Material Properties: Nylon is a versatile thermoplastic known for its strength, flexibility, and resistance to wear and tear. Applications:Commonly used for functional prototypes, end-use parts, and products that require a balance of strength and flexibility.

PA66 (Polyamide 66), and PA12 (Polyamide 12) are all types of nylon, which is a class of polymers known as polyamides. They have differences in their molecular structures, properties, and applications.