Specification

Raw material | ABS |

Technology | CNC machining |

Tolerance | ±0.1mm |

File format | IGS,STP,X-T |

Quantity | 3 pcs |

Lead time | 4-5 work days |

Surface treatment | Matt painting |

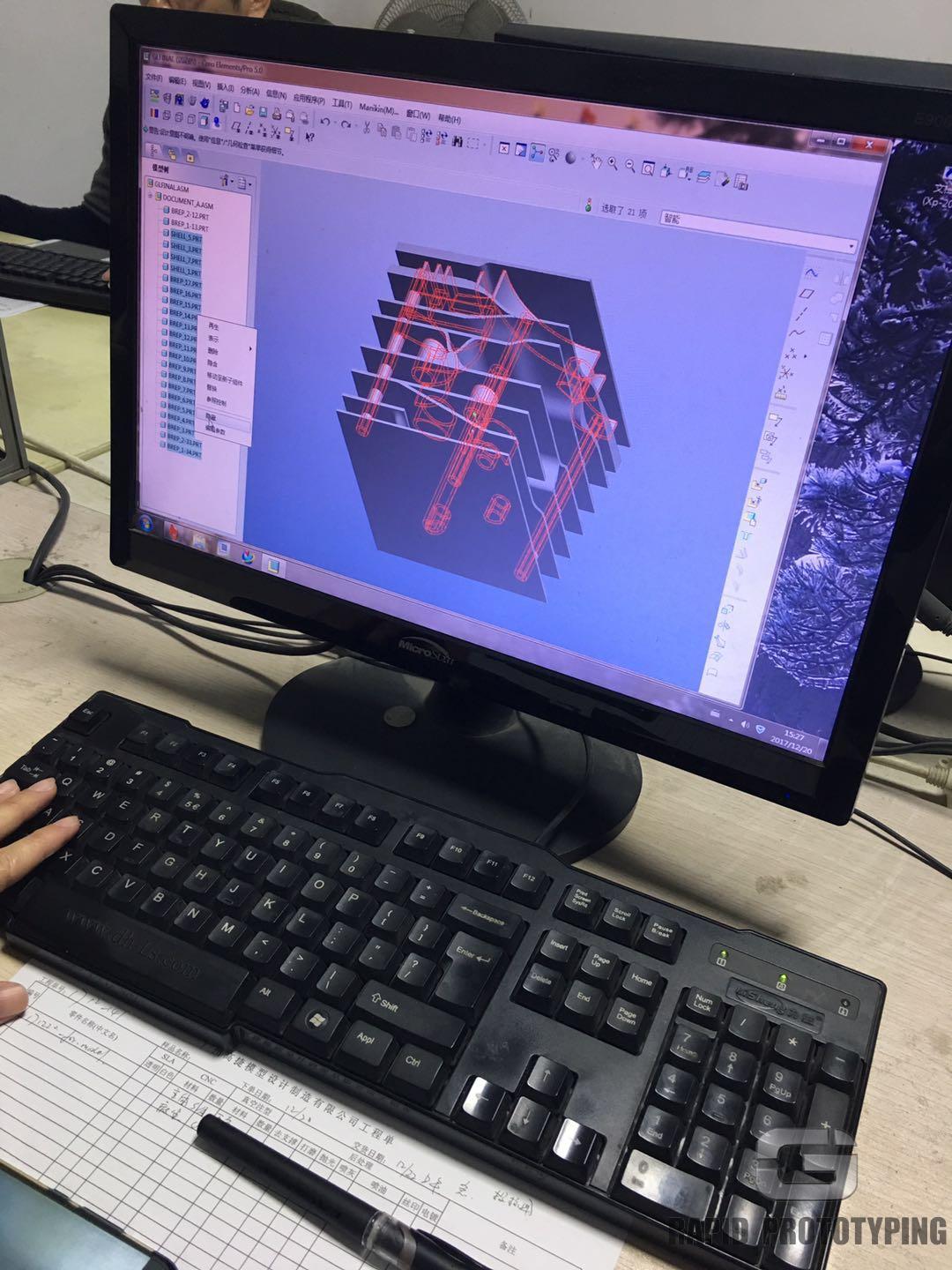

1.Inspection, Programming

When the programming is settled down, we begin machining processing. CNC machining is a subtractive manufacturing process, where raw material is removed with a variety of precision cutting tools to make a part or product.

Copyright © 2025 Design by Gaojie Model | Sitemap