Custom ABS 3D Print Service Plastic Prototype SLA 3D Printed SLS MJF Nylon 3D Printing Services For Shoes Crown Active Figures

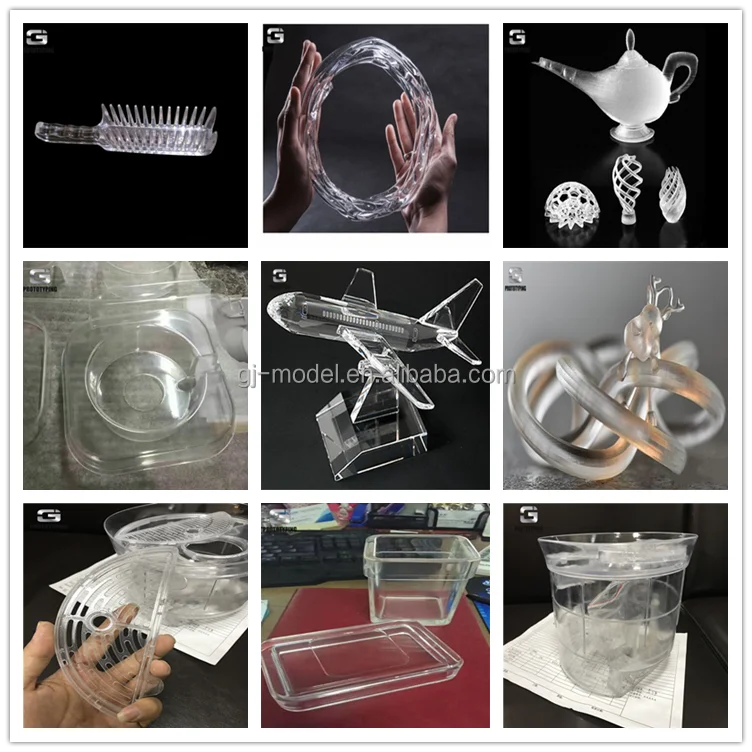

Gaojie-model Transparent Resin Printing:

Transparent resins are used in 3D printing to create parts and prototypes that have a transparent or translucent appearance. This is particularly useful for applications where visual clarity or light transmission is important.

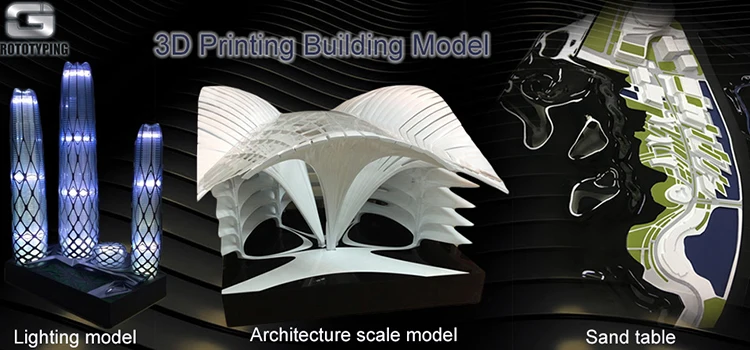

Gaojie-model SLA 3D Printing:

SLA is a type of 3D printing technology that uses a liquid photopolymer resin cured by a UV laser to build up layers of a 3D model. It is known for its high level of detail and accuracy.

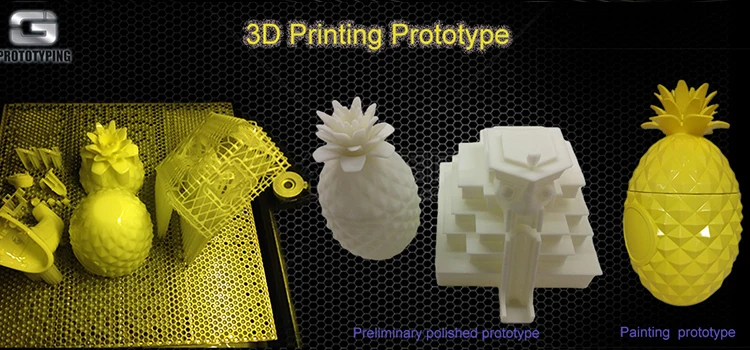

Gaojie-model Rapid Prototyping: Rapid prototyping refers to the quick fabrication of a physical model or prototype for testing, evaluation, and iteration. 3D printing, especially technologies like SLA, is commonly used for rapid prototyping due to its speed and precision.

Gaojie-model 3D Printing Service:

Many companies offer 3D printing services where you can submit your 3D model, and they will manufacture the physical object for you. This is useful if you don't have access to a 3D printer or if you need a high-quality prototype.

If you are looking for a specific 3D printing service that provides SLA 3D printing with transparent resin for rapid prototyping, you can contact us.

Use 3D modeling software (such as AutoCAD, SolidWorks, or Blender) to create a digital 3D model of your prototype. Ensure that your design is suitable for the SLS printing process.

2.File Preparation:

Save your 3D model in a file format that is compatible with the SLS 3D printer. Common formats include STL (Standard Triangle Language) and OBJ (Wavefront Object).

3.Pre-Processing:

Some 3D printing software or online services provide pre-processing tools. These tools may include features for orienting, scaling, and adding support structures to your model.

4.Material Selection:

Choose the appropriate SLS printing material. SLS commonly uses powdered nylon, but other materials like glass-filled nylon, TPU, and more may be available. The material choice depends on the properties you need in your prototype.

5.SLS Printing:

Submit your 3D model to an SLS 3D printer. The printer will follow the digital model's instructions to selectively sinter layers of powdered material, building up the prototype.

6.Cooling:

After each layer is sintered, it's allowed to cool before the next layer is added. This helps ensure that the layers fuse correctly and maintain structural integrity.

7.Post-Processing:

Once the printing is complete, the prototype may need to undergo post-processing. This can involve removing excess powder, cleaning the part, and possibly surface finishing or treating it depending on your requirements.

8.Inspection and Testing:

Inspect the printed prototype for quality and accuracy. Test its functionality if applicable.

9.Iterate if Necessary:

If the prototype doesn't meet your expectations, you may need to go back to the design stage and make necessary adjustments. This iterative process is common in product development.

10.Documentation:

Keep detailed documentation of your prototype, including design files, printing parameters, and any post-processing steps. This information is valuable for future reference or for reproducing the prototype.

Nylon Printing Material Properties: Nylon is a versatile thermoplastic known for its strength, flexibility, and resistance to wear and tear. Applications:Commonly used for functional prototypes, end-use parts, and products that require a balance of strength and flexibility.

PA66 (Polyamide 66), and PA12 (Polyamide 12) are all types of nylon, which is a class of polymers known as polyamides. They have differences in their molecular structures, properties, and applications. Here's a summary of the distinctions:

2.Melting Point:

PA66: Generally has a higher melting point, around 260-270 degrees Celsius.

PA12: Has a lower melting point compared to PA6 and PA66.

3.Mechanical Properties:

PA66: Known for higher strength, stiffness, and better heat resistance compared to PA6.

PA12: Often possesses good impact resistance and flexibility, making it suitable for certain applications.

4.Thermal Stability:

PA66: Offers better thermal stability, making it suitable for applications requiring high-temperature resistance.

PA12: Has moderate thermal stability.

5.Applications:

PA66: Widely used in automotive components, electrical and electronic parts, and structural components requiring high mechanical strength.

PA12: Often utilized in applications such as flexible tubing, oil and gas pipes, and certain automotive components.

| Quotation | According to your drawing(size, material, thickness, processing content and required technology, etc.) |

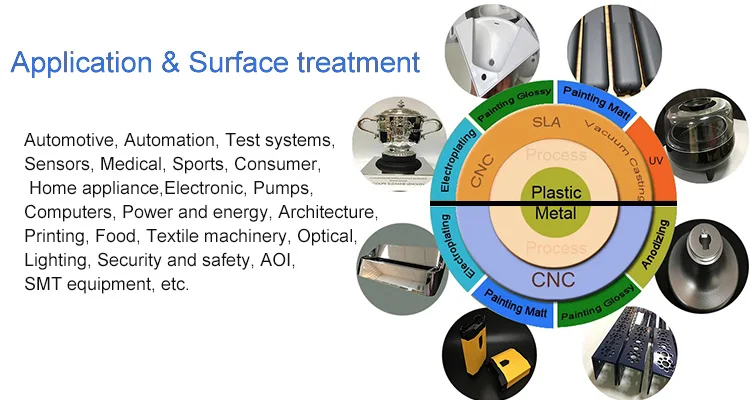

| Available Service | 1.Design |

| 2. CNC Rapid Prototyping | |

| 3. SLS/SLA/3D Printing Prototype Service | |

| 4. High Precision CNC Machining | |

| 5. Silicone Mold (Vacuum Casting) & Rapid Tooling | |

| Surface treatment | Polished, High polishing, Anodizing, Painting, Electroplating, Laser Engraving, Sand blasting, Brushed etc |

| Anodized colors | Do as pantone,Accept customization |

Copyright © 2025 Design by Gaojie Model | Sitemap