What is sla Technology?

SLA is the abbreviation of "stereo lithography apparatus". It is one of the earliest rapid prototyping (rapid prototyping, rp) technologies in the world, and it is also one of the most deeply researched and widely used rapid prototyping technologies. The process is based on the principle of light polymerization of liquid Guang Min resin.

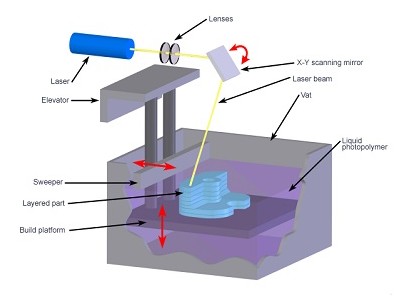

1. The 3D solid model is designed by CAD, the model is sliced by discrete program, the scan path is designed, and the generated data will precisely control the movement of the laser scanner and the lifting platform;

2.The laser beam is irradiated onto the surface of the liquid photosensitive resin according to the designed scanning path by the scanner controlled by the numerical control device, so that after a layer of the resin in the specific area of the surface is solidified, when a layer is processed, a section of the part is generated;

3.The lifting platform is lowered by a certain distance, the solid layer is covered with another layer of liquid resin, and then the second layer is scanned, and the second solidified layer is firmly bonded to the previous solidified layer, so that the layers are superposed to form a three-dimensional workpiece prototype;

4.After the prototype is taken out of the resin, it is finally cured, and then polished, plated, painted or colored to obtain the desired product.

SLA's technical advantages

The photocuring method is the earliest rapid prototyping process with high maturity and long-term inspection.

1.Directly prototyped from CAD digital models, the processing speed is fast, the production cycle is short, and no cutting tools and molds are needed.

2.It can process prototypes and molds with complex structural shapes or difficult to shape using traditional methods.

3.Visualize CAD digital models and reduce the cost of bug fixes.

4.Samples are provided for the experiment, and the results of the computer simulation calculation can be verified and checked.

5.It can be operated online and can be controlled remotely to facilitate the automation of production.

6.Compared with the 3D printing process of hot-melt materials (such as FDM), SLA has high molding precision and smooth surface.

Technical deficiencies: SLA systems are expensive and costly to use and maintain. The SLA system is a precision device that operates on liquids and is demanding in the working environment. Most of the molded parts are made of resin, which has limited strength, rigidity and heat resistance, which is not conducive to long-term storage. The pre-processing software and the driver software have a large amount of computation and are too correlated with the processing effect.

Copyright © 2025 Design by Gaojie Model | Sitemap