3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects by adding material layer by layer, based on a digital model or design. This technology has gained significant traction in various industries due to its versatility, speed, and cost-effectiveness.

Types of 3D Printing Technologies:

Fused Deposition Modeling (FDM): The most common type where thermoplastic filament is heated and extruded through a nozzle to create layers.

Stereolithography (SLA): Uses a liquid resin that is cured layer by layer using UV light.

Selective Laser Sintering (SLS): Utilizes a laser to sinter powdered material (such as plastic, metal, or ceramic) to create layers.

Direct Metal Laser Sintering (DMLS): Similar to SLS, but uses metal powder to create metal parts directly.

Binder Jetting: Powder material is selectively bound together using a liquid binder.

Electron Beam Melting (EBM): A high-power electron beam is used to melt and fuse metal powder.

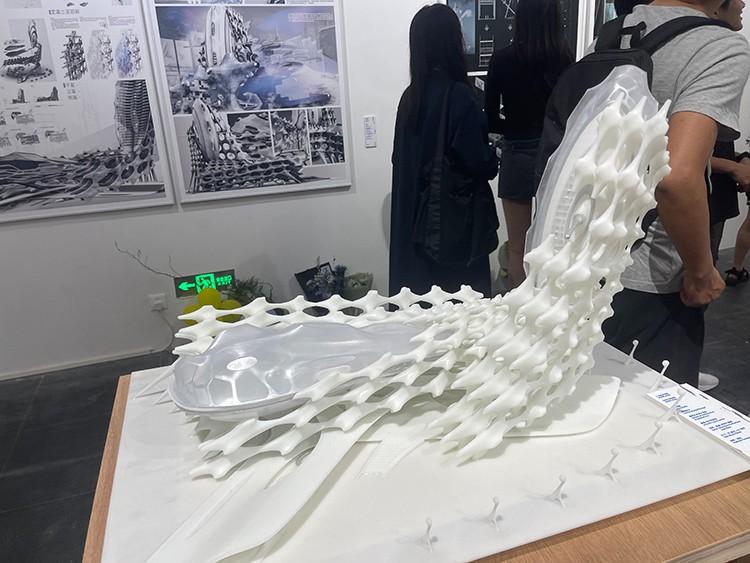

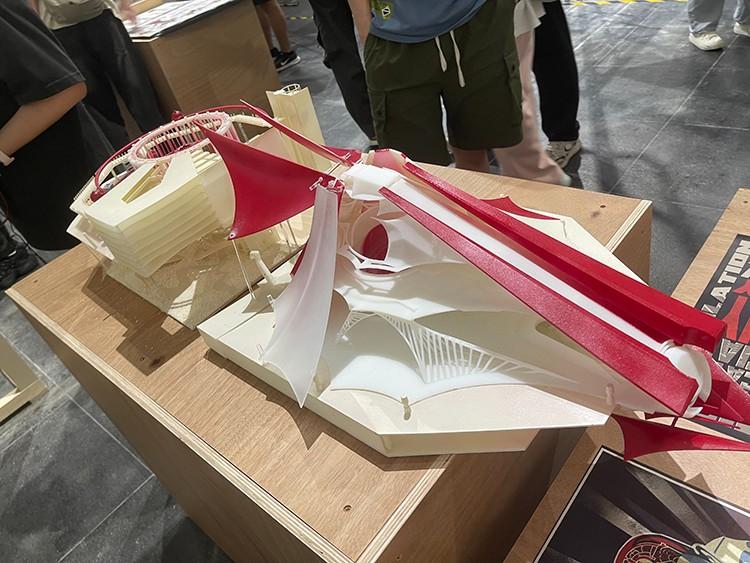

SLA (stereolithography) 3D printing has indeed become an important cornerstone in various industries. Its precision, printing speed and versatility make it a valuable tool in the design and production process, especially for graduate design works that highly value innovation and creativity. At present, 3D printing is also being recognized and used by more and more people.

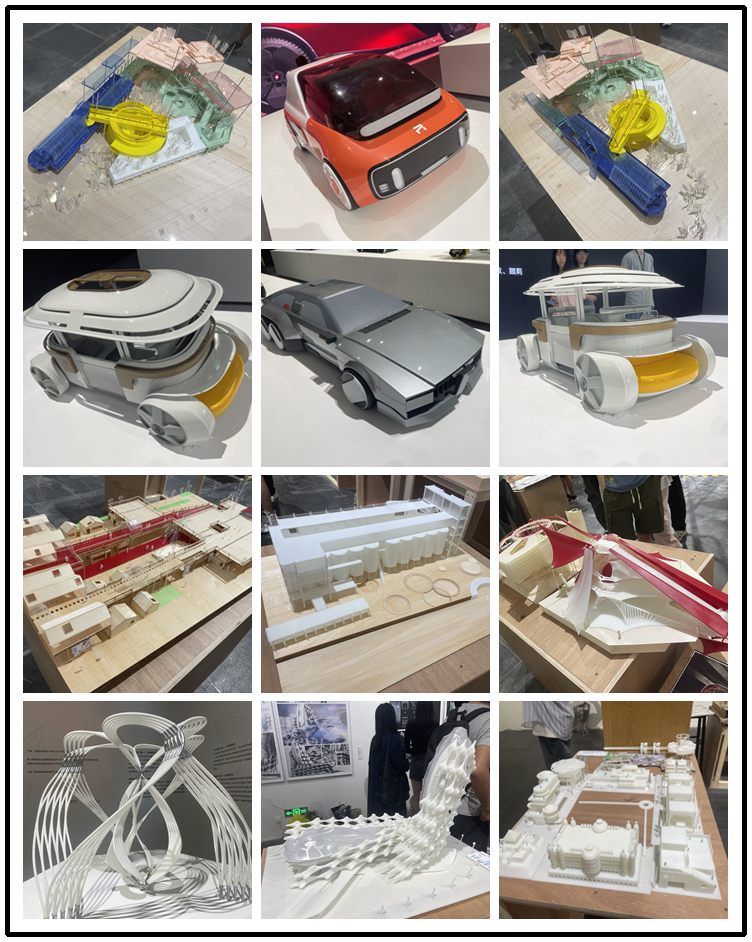

In the construction industry, SLA printing allows architects and engineers to create scale models of complex buildings and structures with precise details, which helps with visualization and planning.

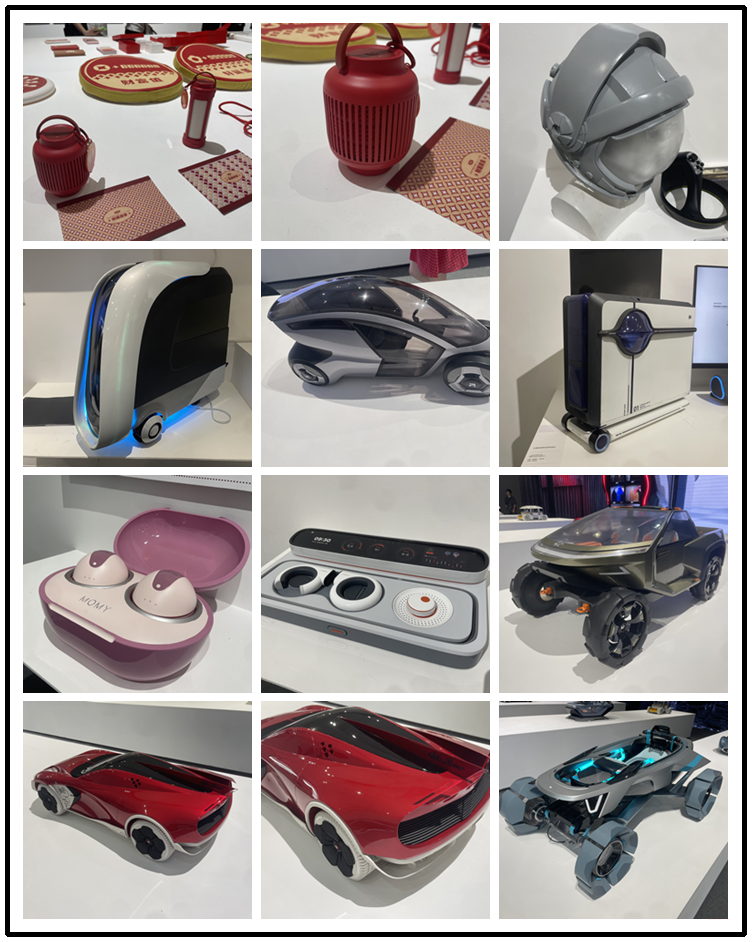

For electronic products, SLA printing can quickly prototype components and housings, facilitating design iteration and testing before mass production.

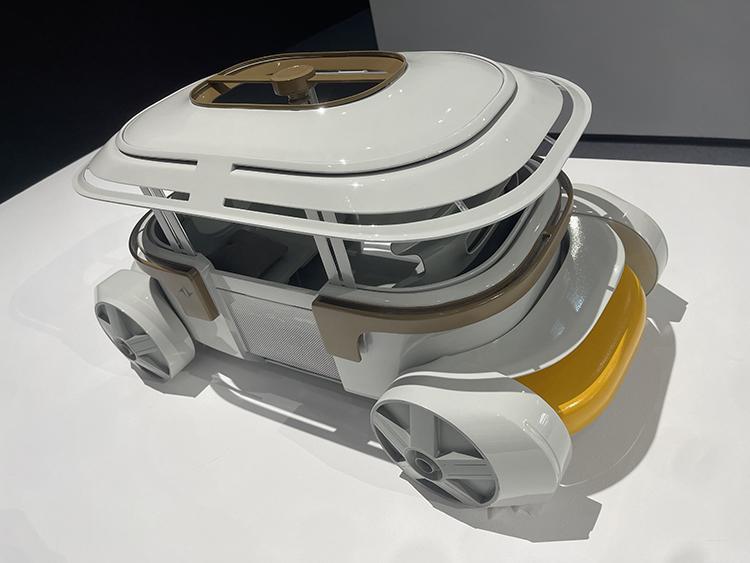

In the automotive field, SLA printing is used to prototype automotive parts and accessories to quickly verify design and assembly.

In the medical field, SLA printing helps produce patient-specific implants, surgical guides and anatomical models for preoperative planning and education, and even more.

In addition, SLA technology is also used to create complex artworks, sculptures and jewelry, pushing the boundaries of creativity and expression.

Overall, the adaptability of SLA 3D printing in different industries highlights its importance in the modern design and manufacturing process.

3D printing has revolutionized the manufacturing landscape by enabling rapid prototyping, customization, and on-demand production, leading to innovation across various industries.

Copyright © 2025 Design by Gaojie Model | Sitemap