Decades ago, the manufacturing industry had to rely on active human labor, effort-extensive steps, and unnecessarily long production periods. However, the manufacturing industry has significantly improved with today’s current technology.

And one of those innovations is computer numerical control or CNC machining. Large production businesses and manufacturers often invest in having their CNC machines. However, more and more business owners are now recognizing the benefits of using a CNC machining service.

If you want to know more about CNC machining, continue reading as we discuss it and its basic concepts in this article.

What Is CNC Machining?

Computer Numerical Control (CNC) machining is a manufacturing process that utilizes computerized controls and machine tools to remove material from a workpiece to create a custom-designed part or product. Here are some key aspects you should know about CNC machining:

1. Basic Process:

Design: The process starts with a digital 3D model of the part created using Computer-Aided Design (CAD) software.

Programming: The CAD model is translated into CNC code (G-code) that guides the CNC machine on how to move, turn, and control tools to produce the part.

Setup: The machinist sets up the CNC machine, securing the workpiece and loading the necessary tools.

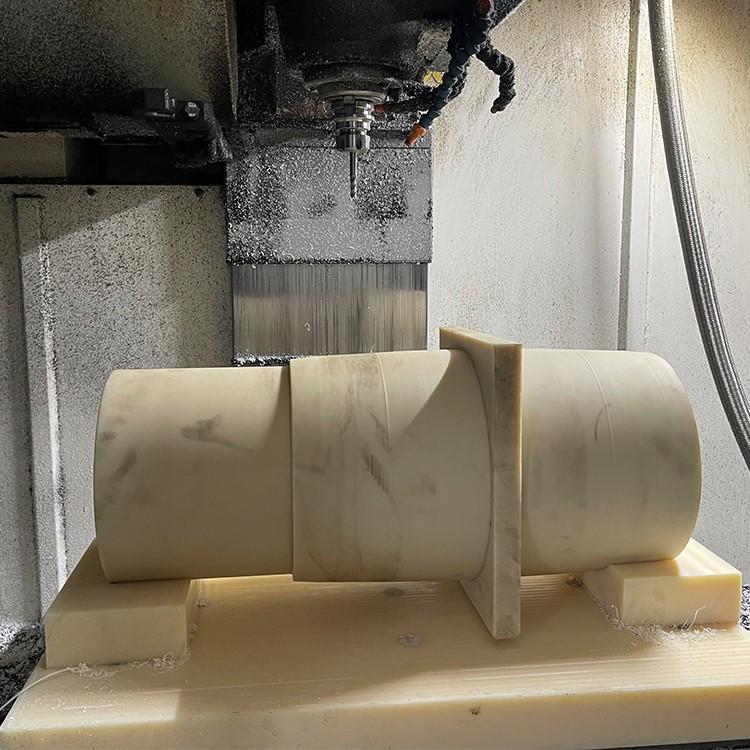

Machining: The CNC machine executes the programmed instructions, cutting away material to shape the final product.

2. Materials:

CNC machining can work with a variety of materials, including metals (aluminum, steel, titanium), plastics, wood, and composites.

3. Types of CNC Machines:

Milling Machines: Used to remove material from a workpiece by rotating a cutting tool.

Lathes: Rotate the workpiece on a spindle while a cutting tool moves in various directions.

Routers: Similar to milling machines but typically used for cutting softer materials like wood or plastic.

Grinders: Precision machines used for finishing operations.

4. Advantages:

Precision: CNC machining offers high precision and repeatability, making it suitable for producing complex and intricate parts.

Efficiency: Once programmed, CNC machines can operate continuously with minimal supervision.

Versatility: Capable of producing a wide range of components across different industries.

5. Tooling:

CNC machines use various cutting tools such as end mills, drills, and lathes. Tool changes are automated, allowing for efficient and versatile machining.

6. Software and Programming:

CAM (Computer-Aided Manufacturing) software is used to generate G-code from the 3D CAD model.

Skilled CNC programmers are essential to optimize tool paths, speeds, and feeds for efficient and accurate machining.

Once the CAD design is completed, the designer exports it to a CNC-compatible file format such as IGES or STEP.

7. Quality Control:

CNC machining often involves quality control measures such as inspection of finished parts using coordinate measuring machines (CMM) to ensure they meet design specifications.

8. Applications:

CNC machining is widely used in industries such as aerospace, automotive, medical, electronics, and prototyping.

9. Limitations:

Initial setup and programming can be time-consuming.

High upfront costs for CNC machines and skilled personnel.

Some complex geometries may require multiple setups.

10. Future Trends:

Advancements in automation, integration of AI, and the use of additive manufacturing alongside CNC machining are likely to shape the future of this technology.

Understanding CNC machining is crucial for those involved in manufacturing, design, or engineering, as it plays a significant role in producing high-precision components used in various industries.

In more technical terms, machining is a type of subtractive manufacturing, which means that the material gets removed during the process. A CNC machine uses fast-moving cutters starting with a block material to quickly carve and cut away materials to create a finished part.

It features a lathe in the center that moves the material into position and is most suitable for products with flat, conical, or cylindrical shapes.

Industries That Use CNC Machining

CNC machining is beneficial for any business or industry that requires uniform parts or components production. Sectors that employ CNC machining include automotive, electrical, mining, defense, industrial machinery, agriculture, clothing, food, and beverage.

In particular, CNC machining is considered very important to engineers in industries where high precision is necessary, including robotics, the medical and healthcare sector, and the aerospace industry.

Essentially, there are no limits to who can use CNC machining. If your business needs a part made with precision or in large quantities, either for production or prototyping, CNC is the right solution for you.

Anyway

There’s no denying how CNC has made the manufacturing industry more efficient and productive. It has become the gold standard in precision manufacturing, thanks to its speed, accuracy, and faster overall production.

Ultimately, CNC machining is the most reliable option for business owners in any industry looking to produce high volumes of accurate mechanical components and parts for production or rapid prototyping .

Copyright © 2016 Design by Gaojie Model | Sitemap